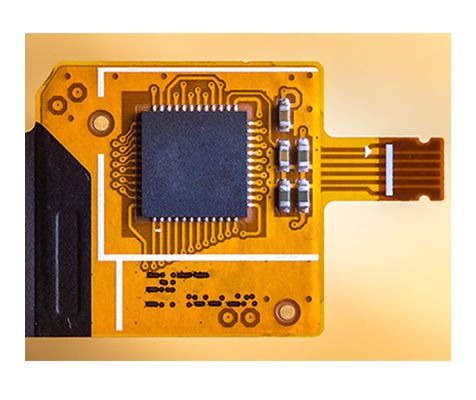

We provide design help at any stage of your project, whether you have complete schematics and CAD files or just sketches on a napkin. We can create schematics, and build part libraries that are customized for flex circuits. We design the circuit with all the features you need (controlled impedance, line length matching, current capacity, etc.) using proper flex design rules and create Gerber files, drill files and all the other files your fabricators and assembly vendors need.

Our documentation packages get rave reviews from fabricators – they get all the important stuff they need to quote and build the circuit. No back-and-forth calls and email.

We work with your mechanical engineers to make sure the length and shape of the circuit is correct so it will reliably bend and move. And we know how to keep costs down – adding folds, shielding and other features to reduce circuit layers and maximize the number of parts on a panel.

We can recommend prototype and production vendors. We don’t take any “referral fees” from vendors – we give an honest opinion on which shops would be best based on the complexity of the design.

If you had a flex circuit designed and built and it doesn’t work we can help! Just send us the CAD files – we can find what went wrong and fix the design so you can get new parts built that work!

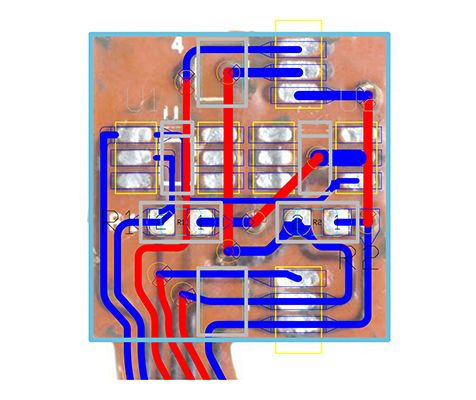

Do you have a circuit that needs to be replaced, but you don’t know who built it and you have no drawings or CAD files? We can create the circuit design from a sample. Even if it has failed or is somewhat damaged we can create a design and often improve the circuit so the new part will be more reliable! And you will have documentation if you need to order more in the future.

Flex circuits are unique—they are neither purely mechanical nor purely electrical. Many PCB designers are available, but very few know the intricacies of flex circuits!