Ninja Flex Circuits – Black Cover and Shielding Films

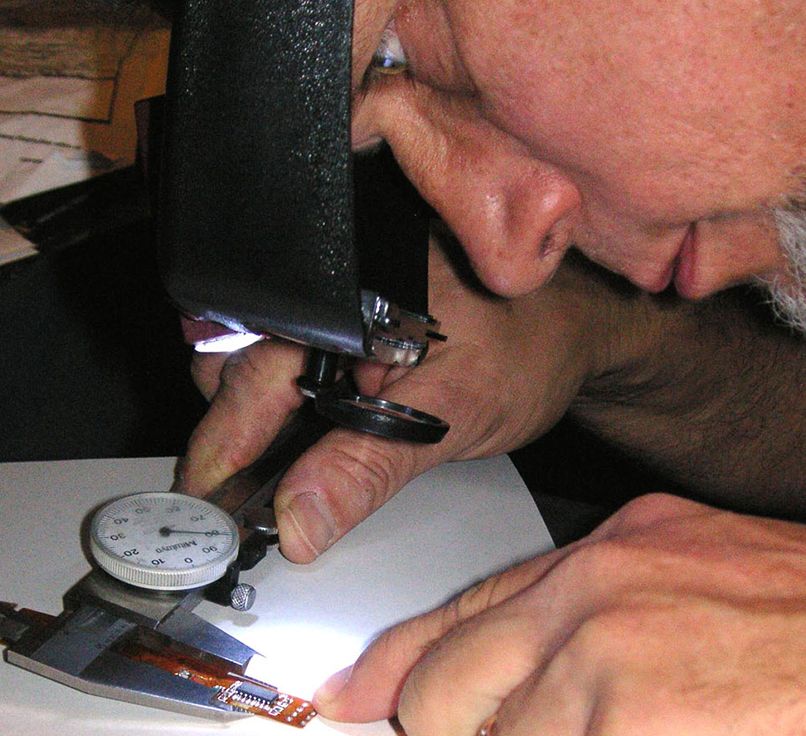

One thing that I’ve always liked about flex circuits is that they look cool! Shiny, orange, and clear you can see those beautifully curved copper traces, unlike their green rigid-board counterparts.

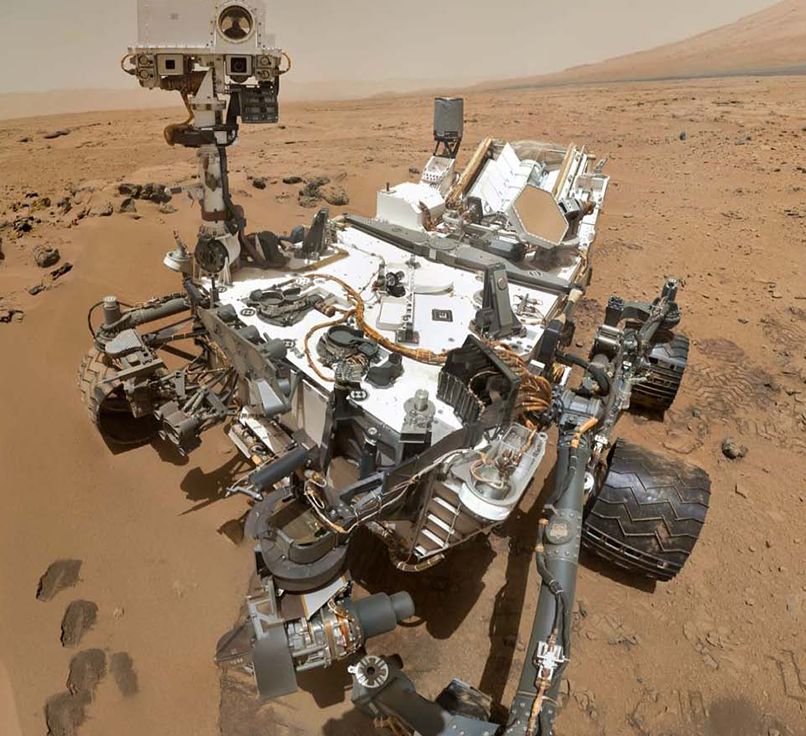

But if you’ve looked inside a smartphone or seen a teardown article on an iPhone you don’t see beautiful shiny flex circuits – you see flex circuits that look like they were spray-painted with black primer.

Do not be deceived by their drab appearance – these are Ninja flex circuits! They have special coverfilms that give them powers to suppress EMI, eliminate glare, control impedance, and reduce cost. They also, disguise and protect intellectual property – it takes a great deal of effort to reverse engineer them and you literally destroy the circuit in the process.